This is going to be a long post where I will attempt to explain to you how I sewed my fringed leather bucket entirely by hand. I’ll be including the cutting dimensions and entire process of making this bag, which is my own design and evolved as I made it. I love it, actually! Which is a good thing, because it took me hours and hours to make.

Disclaimer: This is my first hand sewn leather project, and while I’m going to explain to you how I made the bag and the dimensions used, I can’t guarantee that there aren’t better methods for sewing leather by hand than the ones I used. I’m just getting started in my leather work, and hope to take some classes soon at my local Tandy Leather store to get better at this craft. I’m most definitely not a leather working expert. Just a dabbler! I found all the things I wanted to know to make this bag from my leather working handbook from 1955, a yard sale find. Written by Raymond cherry.

So today, I’m finally using this soft, yet durable brown leather to make this DIY bucket bag. I’ve been wanting a fringed bag for awhile, so why not make my own?

Before we start, I do have a few thoughts on sewing leather with a basic home sewing machine vs. by hand.

I’ve sewn with leather on my home Bernina sewing machine, and also on a special sewing machine designed for sewing ship sails called a Sail Rite. I wasn’t happy with either stitch. I could only use thin all purpose thread with the Bernina, which isn’t really strong enough to hold leather together. When I tried to feed upholstery thread though the Bernina, it got all bunched up underneath, and ruined the leather.

And although the Sail Rite can sew through thicker leather with ease, and uses much thicker thread than the Bernina can, the look of its’ top stitching is really messy, and the stitches tend to get smaller with any tension. So in my opinion, unless you want to invest in a power sewing machine designed specifically for leather, you are going to get uneven looking, unattractive looking top stitch quality, no matter what your skill is with the machine. It’s just too much for the most machines. But if you are one of those people who have it figured out, I’d love to hear your secret.

Typical leather top stitch quality of a home sewing machine.

I have yet to see a project sewn on a home machine with good looking top stitching. Including my own. I also think that seams sewn on the wrong side of leather like a traditional fabric project, look too obvious and not flat enough, without also being top stitched flat on the right side.

It’s very hard to get the leather nice and flat on the outside, even if you glue it and pound it with a hammer. Most bags that I’ve examined have some sort of overlapped or topstitched seam instead.

I would recommend hand sewing thicker leather for the home DIY er. It takes way more time, true, but the results and the seams are so much prettier for home sewn leather projects. And all that pounding when making holes and adding hardware is a great way to release tension!

The tiniest amount of tension when sewing slightly thicker leathers on a home sewing machine makes for a small, uneven stitches. I ruined this jacket below because my machine just could not make a decent stitch on the leather and it would get all jacked up when I tried to feed it upholstery thread. I really wish I could sew it over because I really, really loved this bad ass leather.

I had to use normal thread, which looked so bad and way too thin for top stitching. So countless hours were wasted due to the crappy stitch quality of my machine, which is pretty much top of the line for garment sewing, and my poor jacket is a wadder. It looks nice from far away, but up close, the stitches look terrible. .. Never again! It was supposed to be an EPIC project,too. 14 leather machine needles were broken on this project.

This time I’m hand stitching this leather. I’ll be punching my stitching holes with a small tool then sew my seams with a special waxed thread.It seems the only types of leathers that can do well with a home sewing machine are very thin ones, like lambskin. Definitely not the type I’m working with on my bag here.

So here is how to make the leather fringed bucket bag!

Leather pieces to cut out: ALL PIECES INCLUDE 1/2 SEAM ALLOWANCE

1 piece- 9 inch circle traced from a paper plate.

1 piece- piece 13 inches wide by 28 3/4 inches wide.

2 pieces- 7 inch by 28 3/4 inch pieces for the fringe overlays.

1 piece- 2 inch by 28 3/4 inch piece for the top edge of the bag.

2 pieces- 1 1/2 inch by 36 inch pieces for shoulder straps.

4 pieces- 1 inch by 4 inch leather strips to make D ring straps with. (not shown in photo)

1 piece- 36 inch by 2 inch long strip of leather for strap to go through grommets and tighten bag closed. (not shown in photo).

2 pieces- 1 inch by 3 inch piece for slider for bag strap.

2 pieces – 2 inch by 6 inch piece for fringing and attaching to the edge of the straps that go through the grommet holes.

As far as how much leather to buy, I’ll let you do the math. Just add up the dimensions and remember that leather is sold by the square foot.

I had more than enough leather, so I forgot to figure it out for you. Sorry!

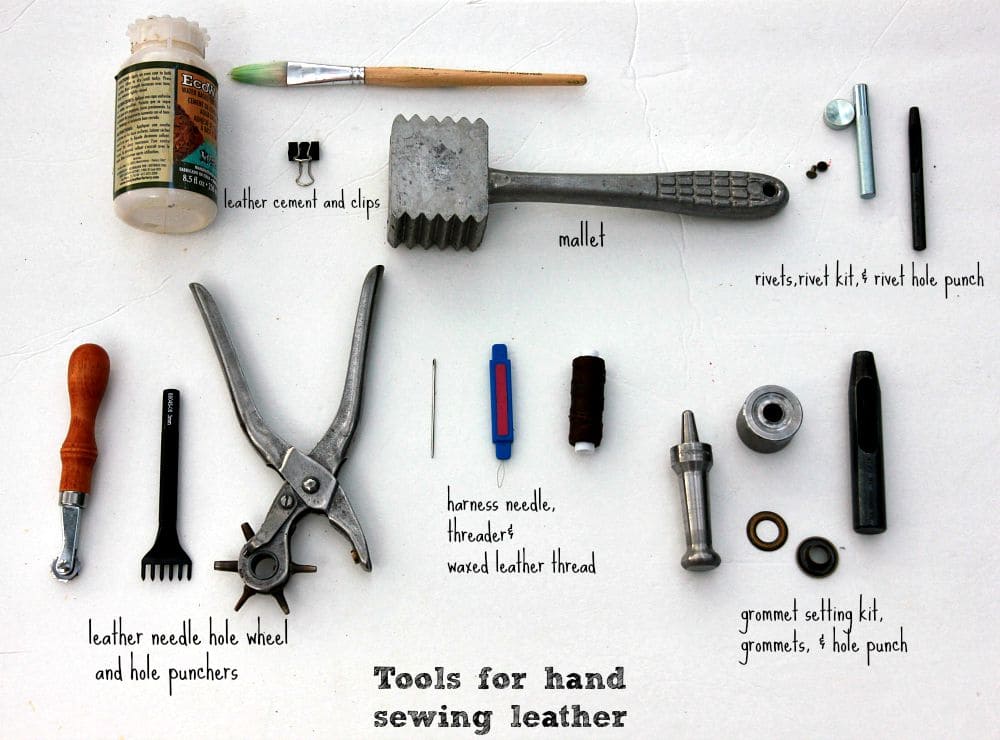

Hardware for bag :

Leather contact cement from Tandy. Water based formula. Unless, you want to fry some brain cells, use this one, Eco Weld.

Brown waxed cotton cord leather thread.

Diamond 6 prong leather punch fork for making thread holes.

12 brass 3/4 inch grommets .

A grommet hole punch and grommet attachment kit.

Small bag of double cap rivets.

2 brass 1 inch D rings

2 brass swivel snaps with 1 inch opening for bag strap.

A mallet for pounding.

Small package of leather harness needles.

I bought my supplies at Tandy leather and at Sav Mor leather in downtown LA.

Cut out the leather pieces as described above.

Cut fringe on the two 7 inch by 28 3/4 inch panels.

Cut the fringe in the two 7 inch wide by 28 3/4 inch pieces. I drew a line 1 inch below the top along the length and cut freehand fringes about 1/4 inches apart. It does take time, but not as long as actually drawing the lines. But unless you are pretty confident cutting straight lines, I’d recommend you draw them first.

Draw fringe placement lines on large body piece.

On the wider long main body piece use a crayon or marking pencil to draw two lines along the length. Draw the first line 1 inch below the top and draw the second line 6 1/2 inches below the top.

Use the leather cement glue to glue the two fringe panels to the lines

Use cement glue to glue the top 2 inch piece to the top of the bag edge. It will end at about where the fringe begins.

Let everything dry for an hour or so.

Punch holes with hole punching fork through glued down fringed pieces and main purse pattern piece.

When you punch the holes with the fork, there will be deep holes going throught o the cutting board so make sure you use a board that you don’t care about trashing.

Thread the harness needle with a long piece of waxed leather thread and sew through holes with a running stitch. Double knot the end and beginning inside the purse. Add some glue to knots so they don’t come undone. You can also use a saddle stitch, which looks more professional, but I decided to make the easier and quicker running stitch for this project, which takes half the time of the saddle stitch and has a Boho look.

Glue down top 2 inch panel to the top of purse and let dry. Punch holes in the top and bottom of it. Sew with a running stitch.

Measure out where you want to place your grommets on the 2 inch top piece. Use mallet to punch holes.

Use the grommet kit and mallet for attaching the grommets.

Glue bag together at sides and sew together. Then glue the bottom to the sides and let dry.

Cut notches out near the bottom of two long straps like below so they can fold over swivel clasp.

Fold over, glue down and let dry.

Now punch holes.

Sew running stitch and knot from behind. apply glue to secure knots. Attach some rivets to make it extra strong and to give a cool look.

Glue each pair of D ring clasp pieces together.

Fold over cemented D ring tab pieces over D rings and make stitch holes and rivet holes with the hole punch fork and the hole punch pliers for the rivet holes. I trimmed mine to make them curved.

Make the same spaced holes on each side of the bag to attach the D ring tabs. Sew on the sides, then attach the rivets.

Cement some upholstery piping to the center fold of the 1 yard piece of leather.

Cement the whole length thing shut on the fold. Let dry, then punch holes and stitch with running stitch. I had to show off that 50’s gossip magazine I just bought at a yard sale…..

Cement two inch by 4 inch slider pieces together, let dry then fold in half. Fold in each side piece to the middle, punch holes, and hand stitch from behind.

To make the fringed tips of the clasp strap, cut fringe on the 1 two 2 inch by 6 inch pieces inch by four inch pieces, leaving the top 1/2 inch uncut. Glue the top uncut edge, and wrap it around the tips of the strap.

Done! It was a long process, but I enjoyed making it!

0 comment:

Post a Comment